Mission Accomplished

Federally funded research shows that generic Geosynthetically Confined Soil (GCS®) structures can have bearing capacities and safety factors more than 10 times those of Mechanically Stabilized Earth (MSE) walls. NCHRP research demonstrated that GCS® walls and abutments can withstand any credible earthquake. State of the art GCS® technology translates into better, safer, quicker, easier and cheaper retaining walls, bridge abutments, box culverts, foundations, rockfall barriers, avalanche and debris flow deflectors, and more. Facing options include natural vegetation, wire mesh, natural stone, concrete block, or sculpted shotcrete.

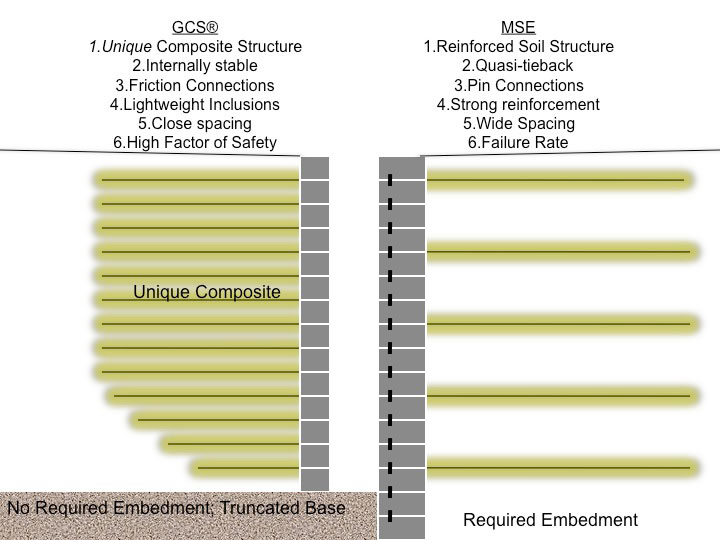

GCS® structures behave as GeoMonoliths or Unique Composites. Unique Composite behavior exceeds the sum of its components. Concrete, for example, is a Unique Composite. We cannot predict the behavior of a concrete pavement with only tests of the cement, water and aggregate. Likewise, we cannot predict the behavior of the layered system of granular backfill and closely spaced inclusions based on the individual properties of each of the elements.

The key to GCS® performance, as demonstrated in the very first “fabric walls” by the USFS in the 70’s, is close (8-12 inch) spacing of geosynthetic sheets in compacted granular backfill. Inclusions provide measureable confining effects in granular backfilll up to about four inches (100mm) from each sheet. Proximal confinement prevents particle dilation and induces intraparticle failure modes (as with concrete and bedrock). This phenomenonexplains why Unique Composite GCS® structures even with the lightest fabrics can be designed to withstand loads over 20 tons per square foot (2.2 MPa).

MSE, on the other hand, is a simple composite and assumes that performance is predictable through element contribution. With wide grid spacing and negligible confinement, backfill particles in MSE structures can more readily dilate, thus stability is maintained mostly through interparticle shear.

MSE has a failure rate, and with the certainty that many standing MSE walls are just marginally stable. This is result, in part, of our early assumption that stronger, stiffer inclusions on wider spacing was equal to lighter inclusions on close spacing and that wider spacing was less expensive to construct. I was a party to this as Chair of the TRB Committee on Geosynthetics 90-97. MSE design criteria remain more or less valid. GCS® is a different technology. Very different.

Our professors, engineers and associations are just now recognizing the grievous error in our decision to use Rankine methods to describe this Unique Composite or GeoMonolithic behavior. The world would be a different place had we understood in the 1970’s to test after construction….we would have recognized and quantified the non linear relationships of spacing. We would not have thrown the light, inexpensive fabrics under the bus in favor of wide spaced grids.

But now with the new FHWA GRS-IBS initiative, the world will finally get to see how powerful this technology really is ....and the benefits will accrue as promised. For all of us that have worked tirelessly with this technology for decades, it is MISSON ACCOMPLISHED!

Herein are reports, papers and essays that add illumination to these topics. It is our goal, our hope, that this site will provide insight and incentive to our next generation of engineers.

I am always available to comment, assist, even visit sites at no cost.

Bob Barrett

Participant in MSE development and Co-Founder of GCS® Wall and Abutment Technology

| TYPE | CLICK FILE NAME TO VIEW ESSAYS | FILE SIZE |

|

GCS® GeoMonolith Theory, Design and Construction | PDF | 191kb |

|

Geomonolith APPENDIX 1 Revisting Research | PDF | 805kb |

|

Geomonolith APPENDIX 2 History of GCS® Research | PDF | 414kb |

|

Geomonolith APPENDIX 3 Practical Design Considerations | PDF | 158kb |

|

Geomonolith APPENDIX 4 Construction and Inspection | PDF | 881kb |

|

Geomonolith APPENDIX 5 Bridges on GRS CGS Geomonoliths | PDF | 1.39MB |

|

Geomonolith APPENDIX 6 Why we do what we do | PDF | 154kb |

|

Letters to the Editor | PDF | 104kb |

PRESENTATIONS

| TYPE | CLICK FILE NAME TO VIEW PRESENTATION IN NEW WINDOW | FILE SIZE |

| GCS Research & Case Studies | Flash | online | |

| Geo Barriers | Flash | online |

Videos

Videos from the Colorado Department of Transportation and the Colorado Transportation Institute.

Written, directed and produced by Robert Barrett. Field support and artistic editing by David Michael Black.

| TYPE | CLICK FILE NAME TO VIEW VIDEO IN NEW WINDOW | FILE SIZE |

| Generic MSB Walls | 24 minutes Generic MSB = GRS = GCS Wall Implementation Guide. A 4-part video series on the technology and overcoming barriers to implementation. |

online | |

| The Great Wall of Denver | 9 minutes A summary of research leading to the famous 1994 Class A prediction symposium where world experts over-predicted failure of GCS walls by factors of 10 to 20. Appearances by Bernard Myles, Vern McGuffy, Barry Christopher, Bob Holtz, Jonathan Wu, Dov Leschinsky, Fumio Tasuoka, Richard Jewell, CJFP Jones, Paul Macklin, Richard Bathurst and Tony Allen and more. |

online | |

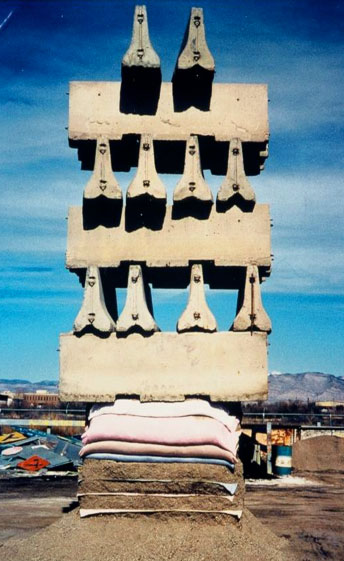

| Bedsheets as Earth Reinforcement | 5 minutes A parody on the practice of strong inclusions on wide spacing. |

online | |

| CTI GCS® Walls | 5 minutes A summary of the benefits of GCS technologies, including a wall in Puerto Rico. Designed and supported by Al Ruckman and Colby Barrett. |

online | |

| Geosynthetics in Jamaica | 9 minutes Shows a GRS/GCS demonstration abutment on 90 feet of "zero" blow count soils featuring Al Ruckman and Rick Valentine. |

online | |

| CDOT Rockfall Research | 21 minutes A summary of the field research that led to our creating the Colorado Rockfall Simulation Program (CRSP) and some funny rockfall segments that almost got me fired. |

online | |

| Rockfall Barriers | 4 minutes Shows yet another powerful aspect of GCS technologies. |

online |

TECHNICAL PAPERS

| TYPE | CLICK FILE NAME TO VIEW TECHNICAL PAPER | FILE SIZE |

|

New Discoveries Can Double the Factor of Safety for MSE Walls and Reduce Costs. | 129kb |

|

Adoption & implementation of GRS design concepts: A consultant’s perspective |

461kb |

|

MSE Retaining Wall Cost DOUBLES with AASHTO's new LRFD guidelines! | 300kb |

|

Open Letter to FHWA and AASHTO on MSE and GCS® Walls | 50kb |

|

Durability of Retaining Wall Facing Blocks | 2MB |

Free Workshops

This presentation/workshop is a summary of 40 years of research by the Colorado DOT, Federal Highway Administration, U. S. Forest Service and several universities in the U. S. and beyond. Topics will include the history of reinforced soil, the evolution of Mechanically Stabilized Earth (MSE) and the next generation of technologies based on the phenomenon of confined soil, Geosynthetically Confined Soil (GCS). Retaining walls to 300 feet high are possible. Bridges that last longer, cost less and are much faster to build are now mainstream in some parts of the U. S. These bridges and box culverts can be built in less than 24 hours in some cases. The presentation concludes with innovations in rockfall mitigation and landslide and erosion control - there are tools and technologies that can cut costs in half. These include the Soil Nail Launcher, SuperNails, SuperMicropiles, GCS retaining walls, GCS Rockfall Impact Barriers and more. Some discussion will be presented on newer technologies for rockfall mitigation and for scour remediation. PDH credits can be provided.

• Robert K. Barrett

Bob is a founder and is Director of Innovation for GeoStabilization International. He was Chairman of NCHRP Project 12-59, charged with preparing Design and Construction Guidelines For Bridge Abutments on Geosynthetically Reinforced Soil. Past Chair of the TRB Committee on Geosynthetics, and the NCHRP project that developed proper closure methods for geotechnical borings. Recipient of 1991 Colorado Governor’s Award for creativity and innovation. Ruckman and Barrett were recipients of the IFAI International Design Award in 1997 for design and construction of a 55-foot-high GRS retaining wall. Co-Recipient of the international 2009 NOVA award from the Construction Innovation Forum for development of GCS bridge abutments. Partner Al Ruckman and Mr. Barrett have been awarded 7 patents, on retaining wall design, on rockfall fences, on earthquake resistant abutments on fiberglass nails, on shotcrete alternatives and on scour micropiles. Co-inventor of the Colorado Rockfall Simulation Program, a program that predicts the behavior of a rock in motion. We have presented GRS, landslide mitigation and rockfall technology transfer programs all over the U. S. and on all continents except Africa. Constructed GRS abutment and wall demonstration projects in several countries.